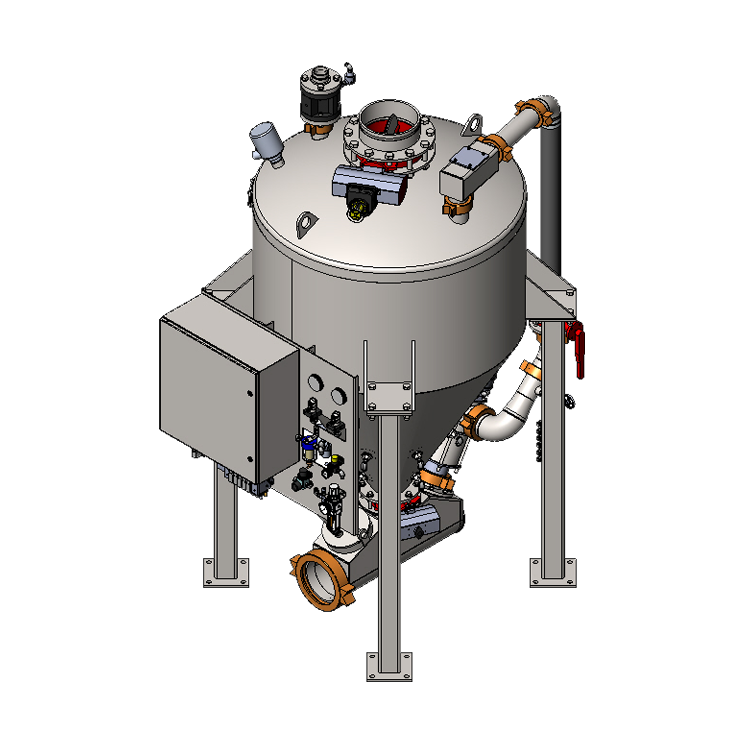

The GF Series is designed for material transfer conditions where a rotary valve is not desired. This material feed device is a high capacity, gravity loaded, semi-dense phase conveyor with a range of capacities up to 150 TPH. It is suited for powder, pellets or granular materials. Medium pressure blower air is used to pressure convey material air at intermediate line velocities and higher material-to-air ratios for less abrasive wear and particle degradation than dilute phase systems.

As the load cycle begins, the HV valve directs the blower air through the convey line. The material flows from the source via gravity into the transfer vessel. The electronic level control regulates filling of the transfer vessel to optimum levels during the load cycle. In the event material flow is interrupted, a backup timer takes over operation.

When the transfer vessel has been filled to the optimum level, the action switches, directing the blower air into the tank. The positive air supply is used to push the material into the discharge manifold where it is fluidized for semi-dense conveying, maximizing particle degradation, reducing line wear and increasing system efficiency.

Excellent replacement for worn out rotary valves in abrasive material applications. Specify: carbon steel, stainless steel or epoxy coated. Ideal for powder, pellet or granular materials. 15 PSIG convey air; 90-100 PSIG control air at 3-5 SCFM.

For simple transfer without the use of feeder, featuring flow enhancing and anti-plugging modulation.

Range of capacities up to 150 TPH.

High-temp materials, abrasive feed powders (cement, fly ash, etc.) or non-abrasive pellet materials.

Designed for a wide variety of applications for bulk silos and bulk bag unloading/in-plant transfer.