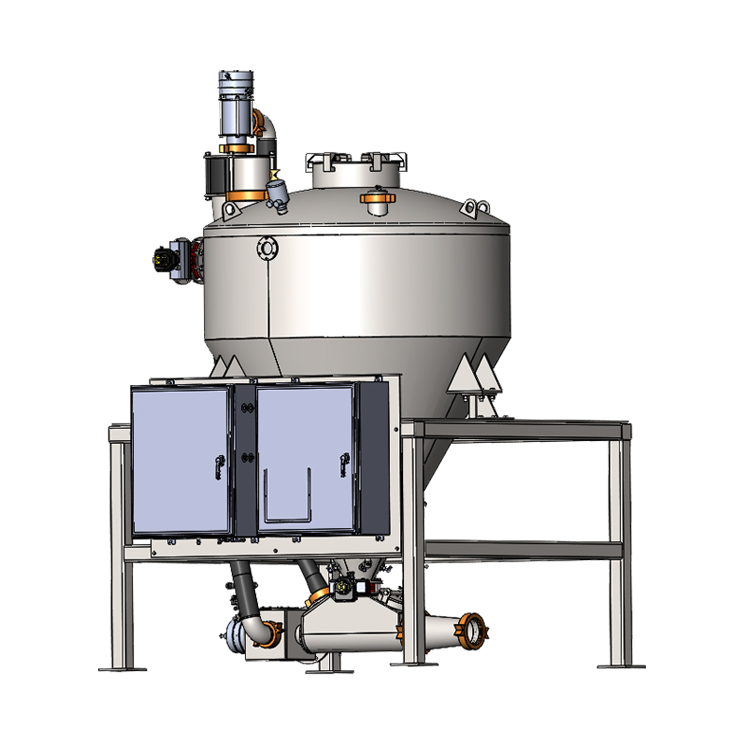

The HC Series conveyor is a high capacity, side inlet, vacuum loaded, semi-dense phase conveyor with a capacity to 80+ TPH. It is best suited for powdered materials that are abrasive or fluidizable. Medium pressure blower air is used to venturi-induced vacuum load and pressure convey air at intermediate line velocities and material-to-air ratios for less abrasive wear and particle degradation. Integral dust separation is included.

As the load cycle begins, the suction valve opens while the inlet and discharge flap valves are closed. The air pressure generates a vacuum by patented venturi action. As the vacuum increases in the transfer vessel, the inlet valve opens. Pulled by suction of up to 15″ of mercury, the material flows from the source into the transfer vessel. The electronic level control regulates filling of the transfer vessel to optimum levels during the load cycle.

When the transfer vessel has been filled to high level, the inlet and suction valves close and the discharge valve opens. The same positive air supply which created the vacuum is used to push the material into the discharge manifold where it is fluidized for semi-dense conveying, minimizing particle degradation, reducing line wear and increasing system efficiency.

Side vents minimize or eliminate pit depth in low head room scenarios. No need for local filters. Standard features include: carbon steel; high-level probe; source aeration; butterfly outlet value; pressure switch on supply air. Portable up to 30 ft3. 15 PSIG convey air; 90-100 PSIG control air at 3-5 SCFM.

HC Series conveyors feature integral dust separation for reduced venturi wear.

Semi-dense conveyor uses medium pressure blower air to convey abrasive and/or fluidizable powders at intermediate line velocities.

Automated controls reduce manpower requirements.

Ideal for low head room scenarios.

Capable of multiple applications, from bulk carrier, IBC and bulk bag unloading to in-plant transfer.