The high-performance QuickSander™ conveys sand under controlled pressure to rapidly service four or more locomotives simultaneously. Units feature automatic operation, abundant on-the platform sand storage for uninterrupted servicing, and a single or dual DPG-B Dense Phase Pneumatic Conveyor.

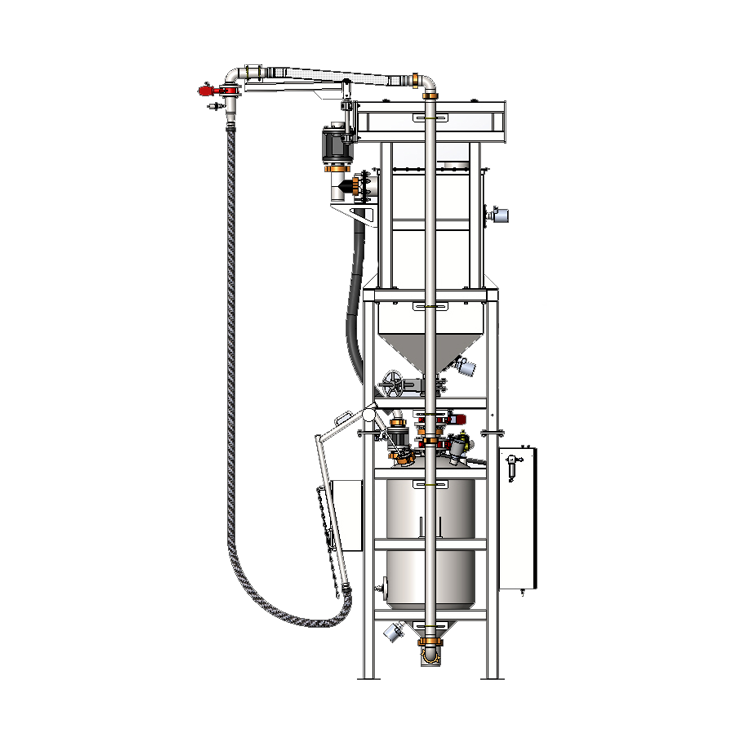

Each QuickSander™ sanding station consists of a supply hopper, which is appropriately sized to meet any instantaneous demands of an arriving consist, and vented to a Cyclonaire dust filter. Below the hopper, we mount a Cyclonaire DPG-B dense phase conveyor that delivers sand to four individually controlled hoses. The hoses are festooned on jib cranes and glide along the cranes on trolleys. So they are easy to move and carry despite their long reach. This configuration can simultaneously service two consists on adjacent tracks. Yardmen simply swivel the cranes, extend the hoses as needed, insert the sanding wand ends into the locomotive sand boxes, push a start button, and then carry on with other work. To avoid overfilling, a unique doppler shut-off system senses when sand boxes are full and shuts off the supply.

With multiple QuickSander™ stations located along service platforms, long consists of locomotives need stop just once to fuel and load traction sand – without time-consuming respotting.

In typical QuickSander™ installations, a Cyclonaire DPG-B Dense Phase Pneumatic Conveyor feeds sand to the individual stations from a central storage silo that can be conveniently located away from the service platform.

High-quality, pneumatic railroad sanding systems designed to transfer sand from storage to locomotive—safely and efficiently.

The QuickSander™ is a high-performance sand dispensing system that can be installed on service track and mainline operations.