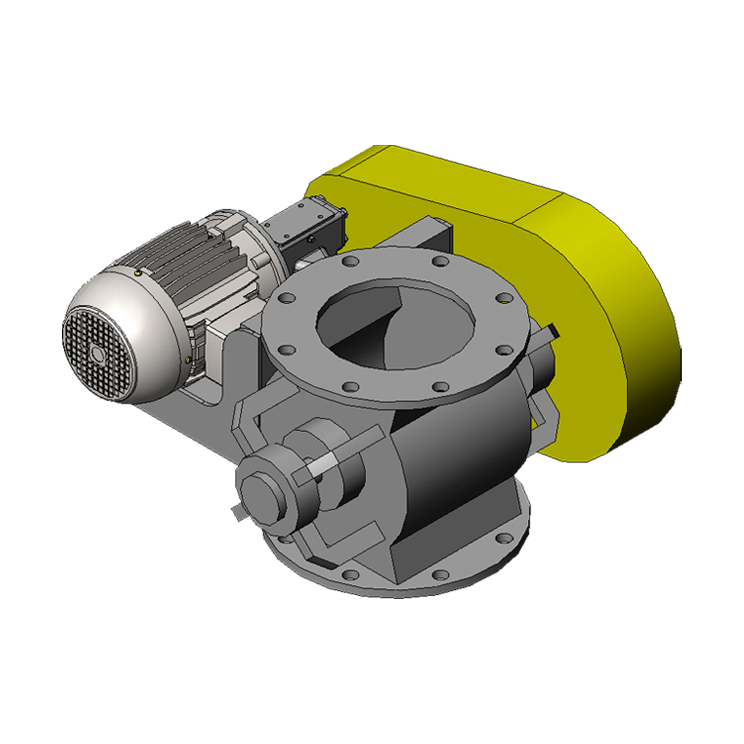

Rotary airlock/feeders are sized for your applications and are available with custom rotor types to suit your applications and materials—powders, granules or pellets. Shaft drives are heavy duty to minimize deflection. Motor and gear reducer are included, sized appropriately for your application. The inlet throat is optimized for excellent product feeding. Airlocks are available in your choice of materials and other specifications.

Dilute-phase conveying and controlling material flow.

Typical consumption is 3-5 SCFM compressed air for purge.